ITS Students Initiate Tempurung Siwalan as a Cloth Mask Filter

Eunike Rhiza Febriana Setyadi, a student of the ITS Chemical Engineering Department, presented her innovative essay results.

ITS Campus, ITS News – The increase in mask waste during the pandemic has an impact on the environment and has the potential to transmit the virus to the surrounding community. Overcoming this, ITS student Eunike Rhiza Febriana Setyadi, through her essay, initiated a cloth mask whose middle layer is given a special filter made from siwalan shell waste.

Masks are one of the items that must be worn during a pandemic, especially if you want to do activities outside the home and meet many people. No doubt, the waste of disposable medical masks has also increased. “Medical mask waste is difficult to decompose and requires considerable resources in its management,” said the student who is familiarly called Ike.

Through an essay entitled The Potential of an Environmentally Friendly Active Carbon Sheet Mask from Siwalan Shell Waste to Reduce the Spread of Covid-19 in Indonesia, Eunike initiated the idea of a cloth mask whose middle layer is given a special filter in the form of an activated carbon sheet. “The activated carbon layer can maximize the effectiveness of filtering impurities, especially viruses,” explained this 2018 Chemical Engineering student.

Furthermore, this student from Tuban explained that this activated carbon could be obtained from the very high cellulose content in the siwalan shell, 89.2 percent. This fruit is also easy to find, especially in Tuban Regency, which produces 5,477 tons per year. “Apart from being affordable, the use of siwalan fruit can also help the local economy,” she said.

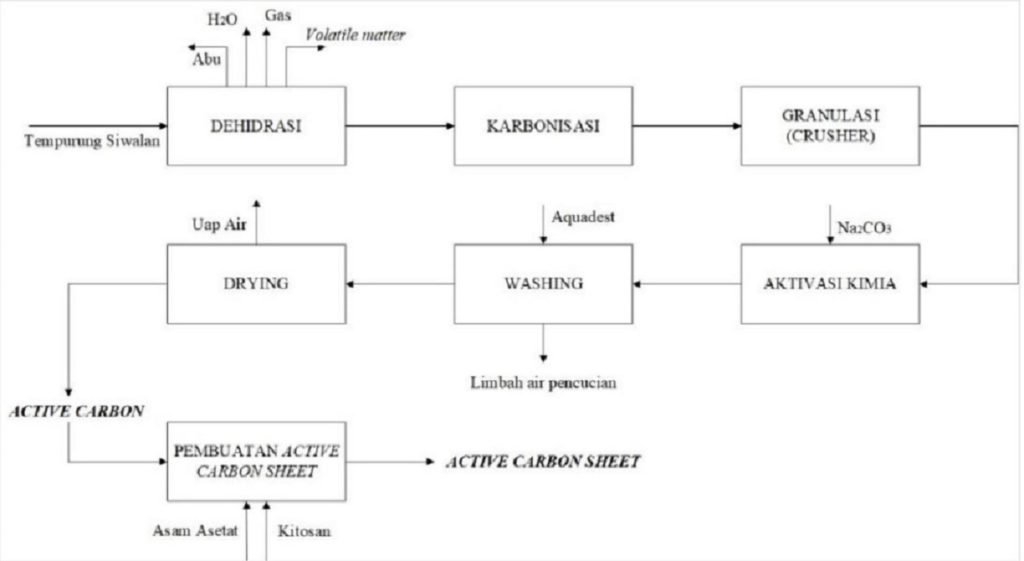

Before processing siwalan shell waste into activated carbon, the shell is first washed to remove the stuck dirt and then dried in an oven at 150 ° C for two hours to remove water content (dehydration process).

Then the siwalan shell will go through the carbonization stage. Finally, a total of 1 kilogram of coir is placed in a closed container and heated in a furnace at a temperature of 300 ° C for an hour. “This siwalan shell will turn into a charcoal shape which is then cooled, milled, and sieved until charcoal is 90 mesh in size,” added the girl born in 2000.

The process of making active carbon sheets from the siwalan shell of the ideas of ITS students

After passing through the carbonization stage, the charcoal obtained will enter the activation stage. This process aims to increase the surface pores of the charcoal, thereby increasing the adsorption power of liquids and gases. At this stage, the carbon is immersed in 25 percent sodium carbonate (Na2CO3). “The use of Na2CO3 is due to its nontoxic nature, so it is environmentally friendly, and the price is affordable compared to other activators,” she added.

More profoundly, Ike explained that the activation was carried out for 24 hours, with the ratio of the mass of charcoal to the volume of the activator being 1:10. Furthermore, filtering is carried out using filter paper, washing the activated charcoal with distilled water, then drying it in an oven at 150 ° C for four hours.

Finally, the siwalan shell that has become activated carbon is formed into thin sheets. Then activated carbon needs to be added to chitosan powder which has been dissolved in 2 percent acetic acid, with a ratio of 50:50. “This chitosan compound is antimicrobial, non-toxic, and has a high adsorption capacity,” she said convincingly.

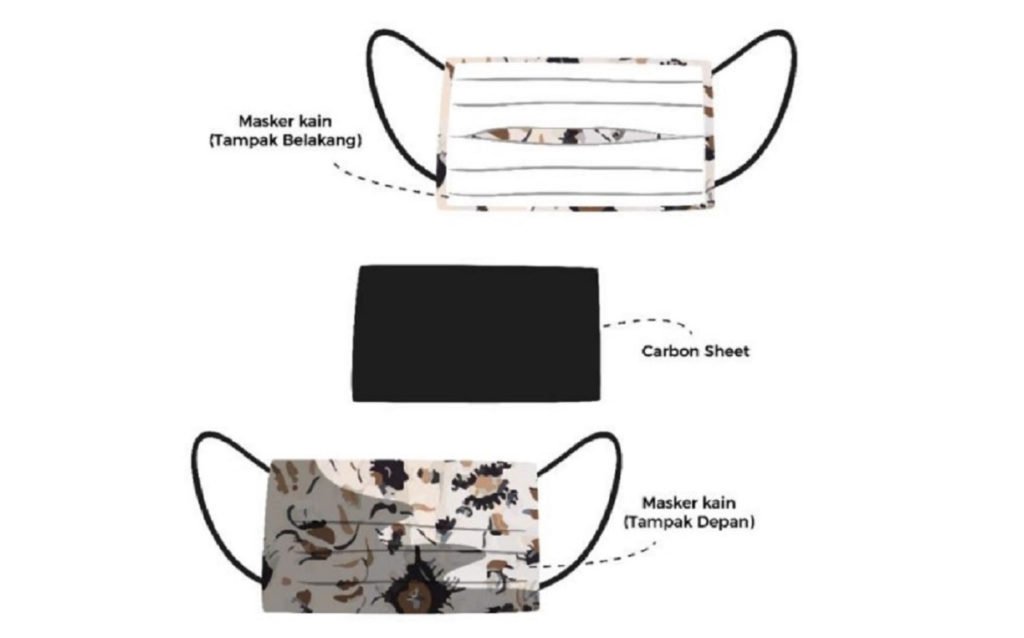

The result of mixing activated carbon with chitosan will produce an active carbon sheet with a pore size of 3.702 nanometers. This pore size effectively filters out various kinds of dust, toxic air, bacteria, viruses about 125 nanometers in length, and even the current coronavirus. “This activated carbon filter can be used as a cloth mask filter within 4-7 days of use,” she explained.

ITS Chemical Engineering students initiated the cloth mask design with active carbon sheets from siwalan shells.

This quite innovative idea had also won second place in the national essay competition of the Indonesian Polytechnic Student Communication Forum (FKMPI) in Lampung some time ago. Ike revealed that the lack of research related to converting activated carbon into thin sheets is the main obstacle. “Until now, I have not been able to find research on this matter,” she said.

Ike hopes that the essay he initiated can be researched further, especially indirectly testing the effectiveness of this mask. “Hopefully, this idea can be followed up and implemented in the general public,” she finished hopefully. (ITS Public Relations)

Reporter: Frecia Elrivia Mardianto

Related News

-

Supporting the Development of Material Processes, ITS Professors Utilize Biomass Waste

ITS Campus, ITS News — Innovation in material processes continues to develop to support society’s need for environmentally friendly

April 29, 2021 15:04 -

ITS Professor Ideas for Bio-Corrosion Control in Marine Structures

ITS Campus, ITS News — Coastal and offshore buildings interacting directly with seawater trigger damage, including bio-corrosion. If not

April 29, 2021 15:04 -

ITS Launches the First Marine Floating Solar Power Plant Prototype in Indonesia

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS)‘s commitment in realizing the energy transition is getting serious.

April 29, 2021 15:04 -

Targeting Champion, Bayucaraka ITS Launches Flying Robot Innovation

ITS Campus, ITS News – The Bayucaraka team at Institut Teknologi Sepuluh Nopember (ITS) has launched four new flying

April 29, 2021 15:04