2021

Cascara is “skin” in Spanish. Cascara is a drink made from the outer skin of coffee. Because the color of this drink resembles tea, so it is called cascara tea and actually does not have a coffee taste at all. The process of making this cascara goes through several processes, namely separation from the main product, namely coffee (pulping), then drying, chopping, packaging, and brewing. From the beginning of the processing, if drying is carried out there are several such as conventional drying which results in a decrease in farmer productivity, or wrong drying which results in different cascara steeping from usual. Therefore drying is very important in coffee processing, without good drying the quality of coffee beans will not be optimal.

The Manunggaling Karso Farmer Group located in Gunung Petung Hamlet, Tutur Village, Pasuruan cultivates coffee with the types of Robusta coffee and Arabica coffee. According to data obtained in an interview with Mr. Winarso, who is the Head of the Manunggaling Karso Farmer Group, 34 tons of coffee beans are produced per year. From 34 tons of coffee cherries produced, there is a huge potential to increase the income of coffee farmers, namely by processing coffee husks into cascara tea and coffee leaves into coffee leaf tea. So far, the Manunggaling Kerso Farmer’s group has been drying cascara conventionally under the sun. This of course requires a long time and a large area, conventional drying can also cause a decrease in the quality of cascara tea.

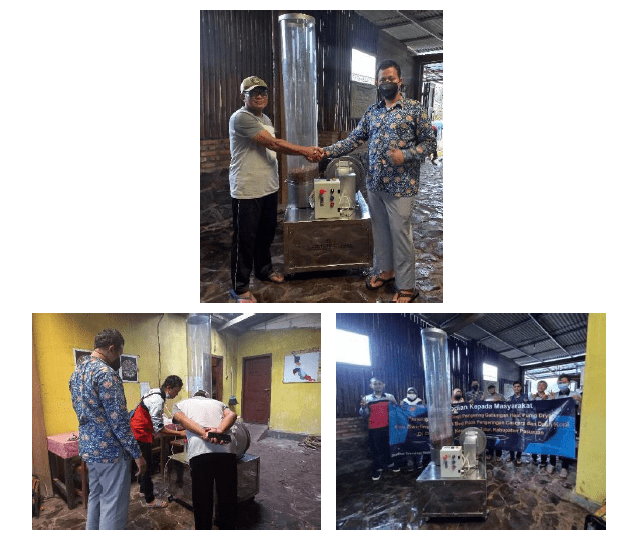

So the ITS ABDIMAS Team provides a solution to increase the productivity of cascara tea by making a cascara dryer. The proposed drying system is a combined method of Heat Pump Dryer and Swirling Fluidized Bed. Because by using a Heat Pump Dryer, drying is not carried out at a high temperature but close to the ambient temperature, but a dehumidification process is carried out first so that the drying air is dry when it will dry the product.

After the machine has completed several internal team tests and is declared ready for use, the team conducts a drying test process which is carried out directly at the partner’s residence. From this ABDIMAS activity, it can be concluded that with a cold drying machine, the time needed to dry 4 kg of wet coffee husks to reach the standard of cascara tea with water content below 10% is 180 minutes. In addition, the dry cascara product produced has a better quality than sun drying and oven drying with temperatures above 50oC. The resulting cascara has a better color, namely a reddish color and has a fresher taste when brewed.