ITS Professors Develop Cellular Materials and Magnetic Machines to Strengthen Industry

Prof. Dr. Ir. Agus Sigit Pramono, DEA, delivered his scientific speech during his inauguration ceremony as the 208th Professor at ITS

ITS Campus, ITS News — Industrial mechanical equipment plays a crucial role in ensuring product quality and safety throughout the production process. Addressing this need, Prof. Dr. Ir. Agus Sigit Pramono, DEA, the 208th professor at Institut Teknologi Sepuluh Nopember (ITS) , has developed innovations involving cellular materials and magnetic systems in machine components.

An alumnus of ITS Mechanical Engineering, Prof. Agus explained that most mechanical devices used in industries today are still made from solid materials and operate through physical contact. In reality, mechanical devices must be adaptable to reduce risks that could harm both industry and the environment. “We need materials that are lighter, quieter, and capable of absorbing high amounts of energy,” he explained.

To meet these challenges, the Madiun-born professor has focused on developing cellular structures in materials and implementing magnets in machine components. “This innovation aligns with the United Nations’ Sustainable Development Goal (SDG) 9, which promotes resilient infrastructure, industrial innovation, and sustainability,” said the lecturer from the Department of Mechanical Engineering at ITS.

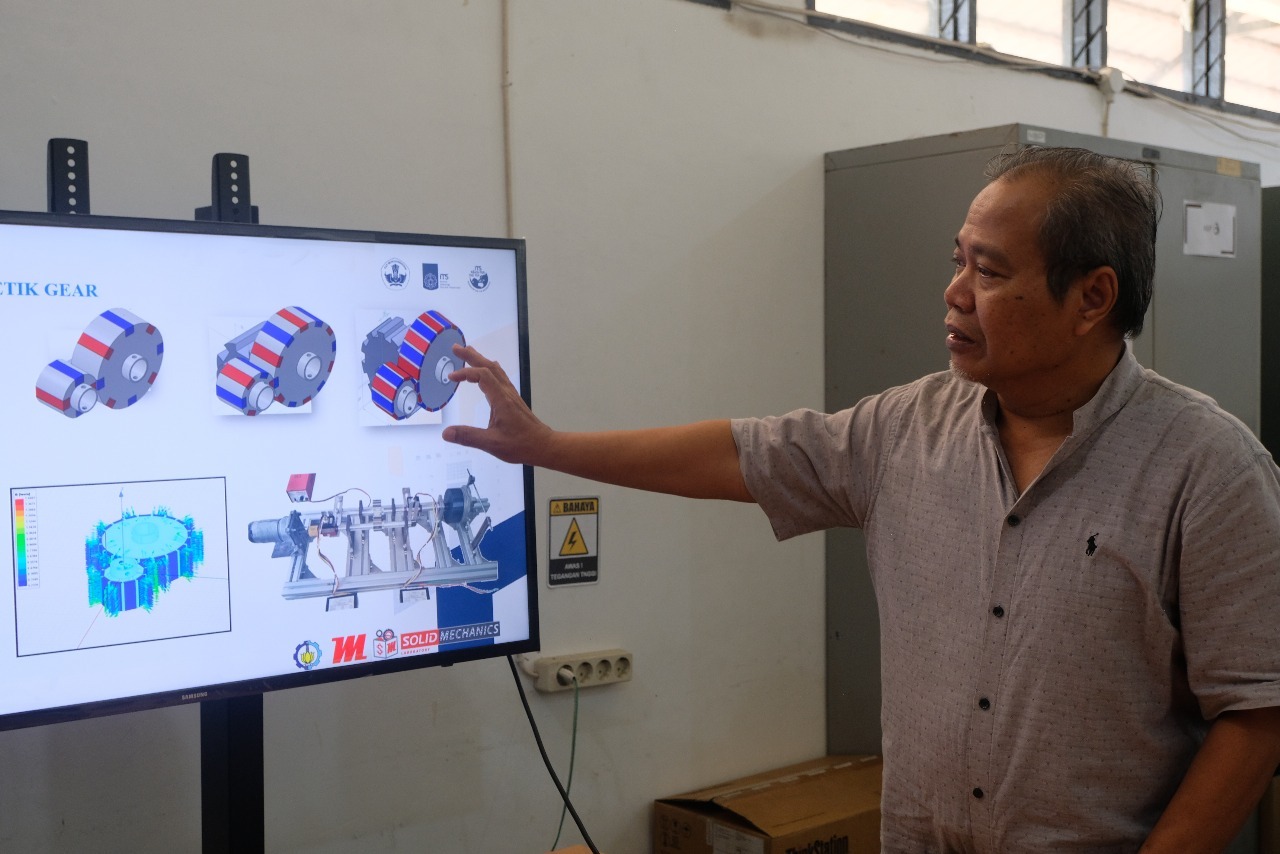

Prof. Dr. Ir. Agus Sigit Pramono, DEA, elaborates on his research in developing and applying cellular and magnetic materials within mechanical components

Cellular materials refer to innovations that transform traditionally solid materials into lightweight, porous structures that can adapt to various functional needs. “These materials have become feasible thanks to advancements in manufacturing technology, especially additive manufacturing, or what is widely known as 3D printing,” he added.

Regarding magnetic components, Prof. Agus introduced the use of powerful neodymium magnets in mechanical systems, allowing movement without physical contact through magnetic force. Neodymium magnets are known to have a magnetic force about 10 times stronger than conventional magnets. “The goal is to reduce noise, friction, and heat generation,” he noted.

In practical applications, Prof. Agus has developed airless tires and lumbar cage implants using lattice structures made from cellular materials. The airless tires are designed for regions prone to sharp objects and lacking access to tire repair services. Meanwhile, the porosity of the lattice structures in the implants enables bone tissue to grow into the material, securely anchoring the implant to the surrounding vertebrae.

Prof. Dr. Ir. Agus Sigit Pramono, DEA, explains the use of magnets in gear machine components

For magnetic components, he has applied the concept to gear systems in industrial machinery. These magnetically-driven gears rotate without physical contact, significantly reducing the risk of mechanical wear or noise. Moreover, the absence of lubricants like oil makes this technology ideal for industries requiring high hygiene standards, such as the food industry.

However, Prof. Agus emphasized that these innovations are not meant to completely replace solid materials in all mechanical applications. Differences in torque capacity mean that certain adjustments are necessary to meet specific industrial requirements. “Adaptation is needed so this technology can be effectively utilized in various industrial sectors,” he said.

In closing, Prof. Agus expressed his hope that these innovations can be widely applied and further developed, particularly in terms of economic viability. He also hopes that the technology can meet the current and future needs of industry. “I hope this will enhance both the quality and efficiency of production processes, now and in the future,” he concluded optimistically. (ITS Public Relation)

Reporter: Bella Ramadhani

Related News

-

ITS Formulates Inclusive Education System Policy for Students with Disabilities

ITS Campus, ITS News — The Sepuluh Nopember Institute of Technology (ITS) has once again demonstrated its commitment to

March 03, 2025 11:03 -

ITS Develops Andal App, a Solution for MSMEs to Manage Inventory

ITS Campus, ITS News — Amidst rapid technological advancements, many Micro, Small, and Medium Enterprises (MSMEs) still rely on

March 03, 2025 11:03 -

Consolink, an Automatic Soil Consolidation Testing Solution Created by ITS Students

ITS Campus, ITS News — A collaboration between a team of students and lecturers from the Sepuluh Nopember Institute

March 03, 2025 11:03 -

Supporting Economic Empowerment, ITS Signs MOU with BSI

ITS Campus, ITS News — The Sepuluh Nopember Institute of Technology (ITS) continues to strengthen its tangible and sustainable

March 03, 2025 11:03