ITS Students Promote Resource Saving Construction Strategy

(from left) Ahmad Wisam Abdillah, Kevin Adinugraha Sudijar, and Mukhamad Zadhi Nashruddin

ITS Campus, ITS News – Construction of apartments is currently needed to support community housing due to increasingly narrow land. However, it is undeniable that building such infrastructure requires large resources. Seeing this, the student team of the Institut Teknologi Sepuluh Nopember (ITS) offered an innovative apartment building project using fairy formwork and precast plates .

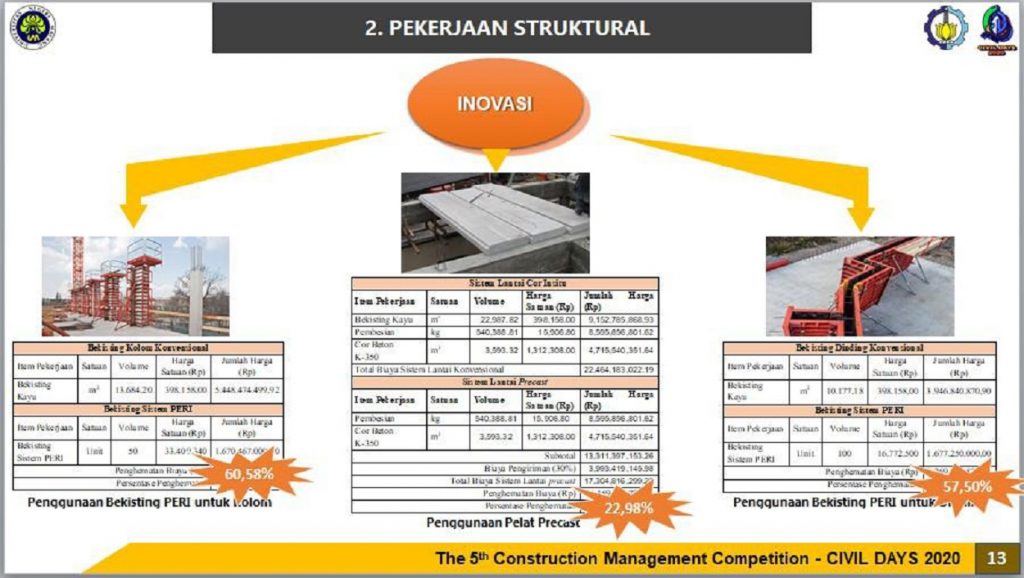

They are Ahmad Wisam Abdillah, Kevin Adinugraha Sudijar, and Mukhammad Zadhi Nashruddin. The three retainers from the ITS Civil Engineering Department offered the two innovations for the construction project of an apartment in Malang City. Ahmad Wisam Abdillah said that the fairy formwork innovation is a type of formwork made of steel so that it can be used repeatedly until the apartment project is completed.

The student who is familiarly called Wisam said that this PERI formwork shape is almost the same as conventional wooden formwork that is generally used. However, this type of formwork is considered to be more durable and can minimize the disconnection of the formwork. “In addition, this formwork also reduces the possibility of leaks in the formwork,” he said.

In this project, this type of formwork is used to design the perimeter fence and apartment columns. The goal is to reduce the duration of the project so that it is completed faster. “This is because this apartment has 12 floors and there are two underground floors for a car park,” he explained.

(Left to right) Portrait of the team’s innovation, namely fairy formwork for columns, precast plates, and fairy formwork for basement walls and perimeter fences

Apart from reducing project time, this fairy formwork is also considered to be more efficient in terms of resources than timber formwork. “The use of this formwork causes less wood to be wasted and can reduce construction costs,” said the 2017 class student.

Not only formwork but the team also launched an innovation in factory-printed precast floor plates . This plate is used as an innovation from conventional in situ cast plates which are considered slow processing time. ” Just install the precast plate, thus accelerating the project duration,” he said.

It is through the time efficiency of innovation that project scheduling time can also be reduced. So that the utilization of project human resources (HR) can be maximized. “We predict the project can be completed within 20 months and 22 days,” said the student guided by lecturer Mohammad Arif Rohman, ST. M.Sc. This PhD.

Through this innovation, the Samala60 team won first place in the 5th Construction Management Competition which was held by the State University of Malang on the 2020 Civil Days. He also hopes that this innovation can be a means for Indonesian civil engineering students to understand the implementation of civil science in the field. (vi/nadh/ITS Public Relations)

Related News

-

Supporting the Development of Material Processes, ITS Professors Utilize Biomass Waste

ITS Campus, ITS News — Innovation in material processes continues to develop to support society’s need for environmentally friendly

December 11, 2020 17:12 -

ITS Professor Ideas for Bio-Corrosion Control in Marine Structures

ITS Campus, ITS News — Coastal and offshore buildings interacting directly with seawater trigger damage, including bio-corrosion. If not

December 11, 2020 17:12 -

ITS Launches the First Marine Floating Solar Power Plant Prototype in Indonesia

ITS Campus, ITS News — Institut Teknologi Sepuluh Nopember (ITS)‘s commitment in realizing the energy transition is getting serious.

December 11, 2020 17:12 -

Targeting Champion, Bayucaraka ITS Launches Flying Robot Innovation

ITS Campus, ITS News – The Bayucaraka team at Institut Teknologi Sepuluh Nopember (ITS) has launched four new flying

December 11, 2020 17:12